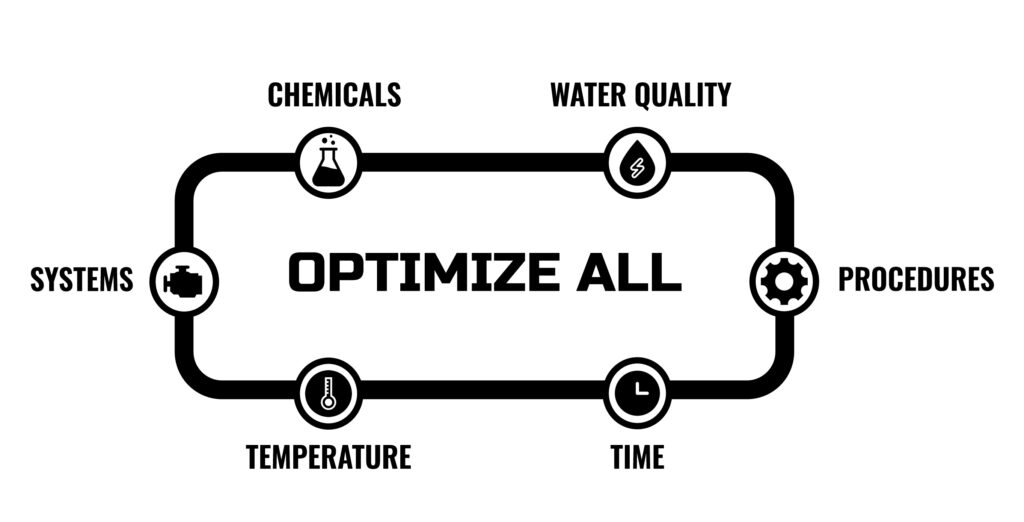

To consistently achieve a cleaner, dryer and shinier car with a great show, there are six factors that must be properly audited, adjusted and aligned to produce an optimal wash quality — chemicals, systems, water quality, procedures, temperature and time. Each of these six elements is linked to each other, so when one or more are not optimized, problems compound and wash quality instantaneously deteriorates. Additionally, these components need to be monitored and maintained regularly to achieve consistency in wash quality.

Today’s professional carwashes are highly sophisticated, automated and robotic operations. Modern-day carwashes need to be finely tuned machines, much like a race car that requires constant attention as the equipment is stressed and the odometer racks up the miles. But, with the help of technology and a skilled technician, site managers can be electronically alerted when any of these components fall outside of an acceptable parameter and make the necessary adjustments.

Most of these factors have a tolerance level before a real issue surfaces. However, once one of these elements falls outside an acceptable tolerance level, that factor and others linked will need to be diagnosed and optimized. Below are some key attributes worth considering when optimizing wash quality at your operation.

Chemicals

- Chemical programming is based on water quality, delivery systems, environmental conditions and chemical action required (clean, dry, shine or show). The type of cleaning agents and concentration levels will dictate chemical actions.

- Chemicals fall into two basic categories, acids and alkalis, which vary in scale by pH level. High pH products are better for attacking organics. Low pH products are better for mineral/oil-based contaminants.

- Chemical applications need to be sequenced to manipulate the surface tension of the vehicle from start to finish. The surface tension should remain high during the cleaning phase and at the lowest setting during the shine and dry phase of the wash.

Systems

- Mechanical, plumbing and electrical systems need to be sized, positioned and programmed correctly to achieve peak performance.

- Water/chemical delivery lines from the dispensing system to arches, applicators, wraps and mitters must be sized based on the length of run distance. Proper backpressure is key for all delivery systems.

- Friction-based systems rely on cloth, brushes and bristles to wash the vehicle, while touchless wash systems rely on water pressure impingement and volume to do the same job.

Water quality

- Generally speaking, the better the water quality, the better the chemical action on the vehicle.

- Hard water will decrease cleaning and create mineral deposits. Reclaim and reject water are best for high-pressure rinsing, and reverse osmosis (RO) and soft water are ideal for shining and drying.

- As the water hardness level rises, the chemicals become less efficient with more solids in the water and therefore more product is needed to achieve the same degree of cleaning.

Procedures

- Proper bay/tunnel configuration (order and distance of arches, wraps, mitters, rinsing, blowers), chemical applications and chain speed order are critical to the ultimate wash quality.

- Chemical application and blower nozzle configuration must be sized and properly placed to maximize coverage, and the blower vibration (clogged intake) should be constantly monitored and maintained for peak performance.

- Chemical dispenser back pressure (indicating a clog or a leak) and air pressure must be monitored and regularly maintained to achieve consistent wash quality.

- Pre-rinsing all detergents off the vehicle before applying dry products is imperative for the dry products to work efficiently.

Temperature

- The higher the temperature, the lower the viscosity of the chemicals and vice versa.

- As the viscosity increases, more chemistry is required to do the same job and the opposite is true, as the viscosity decreases, which may require a tip change during vast swings in temperature.

- Some bays/tunnels need to be heated and/or utilize rollup doors or heat the water to optimize chemical action.

Time

- Time needs to be carefully balanced between chemical dwell time, temperature and mechanical action.

- Chain speed must be adjusted to balance throughput and chemical performance (clean, shine, dry and show).

- As dwell time increases (to a limit of diminishing returns), the cleaning power increases.

A common misconception about achieving optimum wash quality (or a lack thereof) is that it is just one factor at play. However, it is always a combination of things. The best way to avoid inconsistency in quality is to have constant monitoring and regular maintenance of core equipment by an experienced technician, who can be in short supply and expensive. Employing monitoring technology is the best way to reduce labor and get instant notifications of any issues. The biggest benefit to optimizing your tunnel or bay through monitoring technology is the reduced downtime, consistent wash quality and a prolonged life of equipment, and an expert technician specializing in tunnel operations can help the operator achieve this.

Michael O’Donnell is a 37-year veteran of the carwash industry, touching every aspect of the business, inclusive of: ownership, operations, technician, instructor, product development, equipment sales, distribution and manufacturing. He is a principal with Newport Beach, California-based Smart Solutions, Inc., an innovative “fluid technology company” serving the professional carwash industry, specializing in advanced chemistry, technology and support. Learn more at smartsolutions.net or contact Michael O’Donnell at [email protected].